APPLICATIONS The use of infra-red technology can be employed in a variety of applications across a wide range of different industries.

|

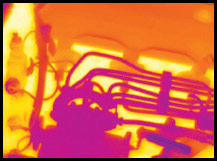

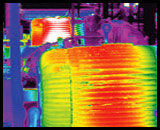

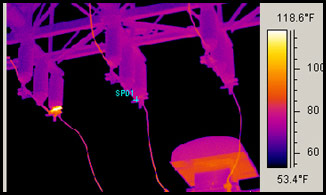

Worn bearings and mis-aligned pulleys can cause unexpected downtime usually at periods when it is least expected and highly unwelcome. We can predictively identify areas of potential problems and literally see it before it becomes a problem! Thermal imaging is a valuable tool in preventive maintenance of electrical, mechanical and structural systems, able to help detect problems, prevent unscheduled downtime, guide needed corrective action and increase plant safety.

ADDITIONAL INFORMATION:

|

![]()

INFRARED CERTIFIED

Level II Certified Thermographer

CEM® Certified Energy Manager

AHIT CERTIFIED

Master Building Inspector