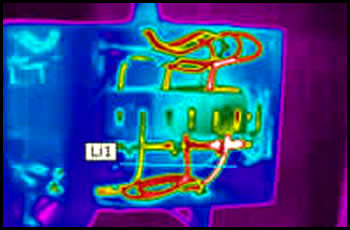

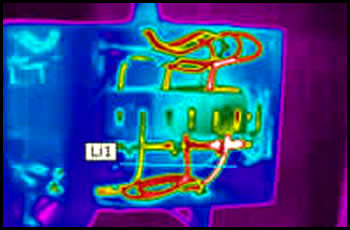

CASE STUDY 1 - ELECTRICAL

Our client required

a thermal survey to comply with insurance policy

changes. We completed the entire survey in one

morning with minimal disruption. The report was

completed that afternoon and his report, highlighting

overloaded components, out of phase power supplies

and poor connections, was on his desk the next

morning. Not only did this meet his insuarnce policy

requirements but allowed him to plan a maintenance

schedule keeping shut down time to a minimum.

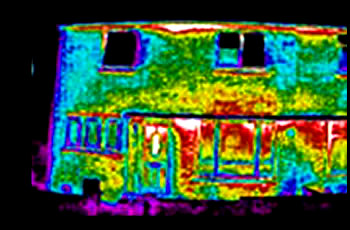

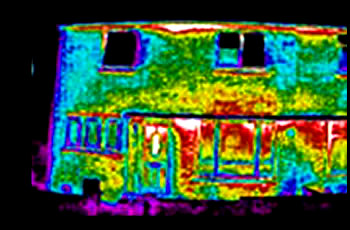

CASE

STUDY 2 - ENERGY EFFICIENT ASSESSMENT

Infrared thermography

is the perfect tool for assessing energy efficiency & provides

visual evidence of poor insulation.

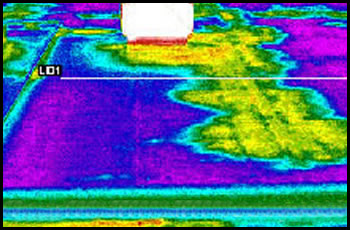

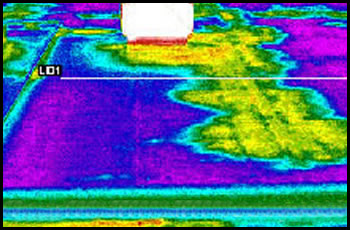

CASE

STUDY 3 - FLAT ROOFING

Our client was

undecided whether to strip or overlay his customers

1500m² flat roof. A roofing contractor had

informed him that it showed considerable moisture

ingress below the waterproofing and recommended

a complete strip and re-lay. Unconvinced of this

information he commissioned WCTI for a thermographic

survey which revealed moisture ingress in only

isolated areas equivalent to 26m². These areas

were successfully stripped and re-laid saving our

client $76,000 on phase I alone.

Our thermographic

surveys can detect trapped moisture below waterproofing,

damaged/missing insulation, hidden structural features

and many other thermal anomalies.

CASE

STUDY 4 - INSULATION ANALYSIS

In this example

we surveyed mulitple homes using infrared thermography

to asses the condition of the cavity fill insulation.The

survey took one day on site with no disturbance

to the occupants. All internal heat sources and

room layouts were taken into account during analysis

and confirmed that 60% of the homes required attention.

Our re-test then

proved that the work had been carried out satisfactorly.

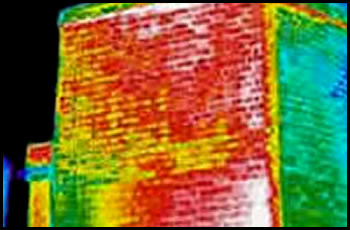

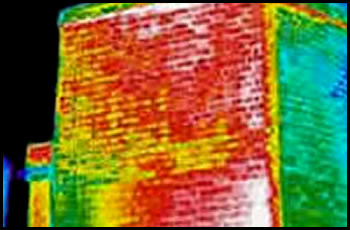

CASE

STUDY 5 - POROUS BRICKWORK

Infrared thermography

can detect porous brickwork quickly and inexpensively

with just one image. Because you have a graphic

record of the areas effected you can put together

a detailed program of repairs.

Entire buildings

can be assessed before and after repairs, ensuring

all works have been carried out correctly.

CASE

STUDY 6 - VOIDING WITHIN WALLS

Infrared thermography

and ground penetrating radar are ideal for locating

voids within structures. Traditional methods involve

time consuming destructive techniques. These methods

are not always possible when analysing historic

and listed buildings.

Using thermal images

we are able to pinpoint the locations of the wall

voids, reinforcements and other hidden structural

features. |

![]()